- Home

- Product

- EPDM Series

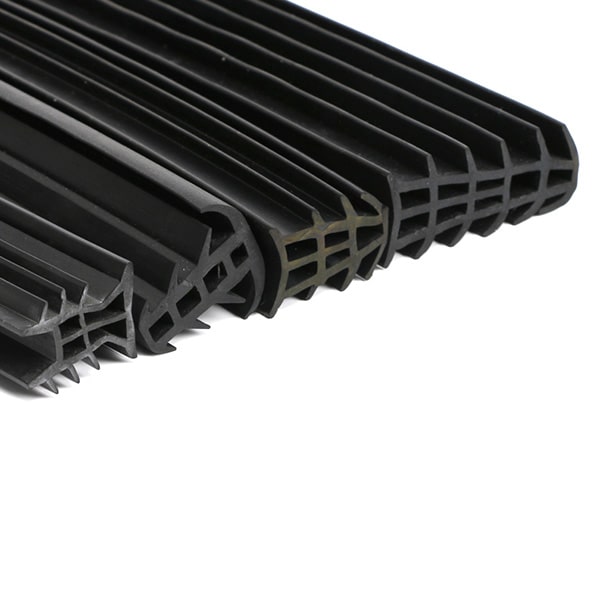

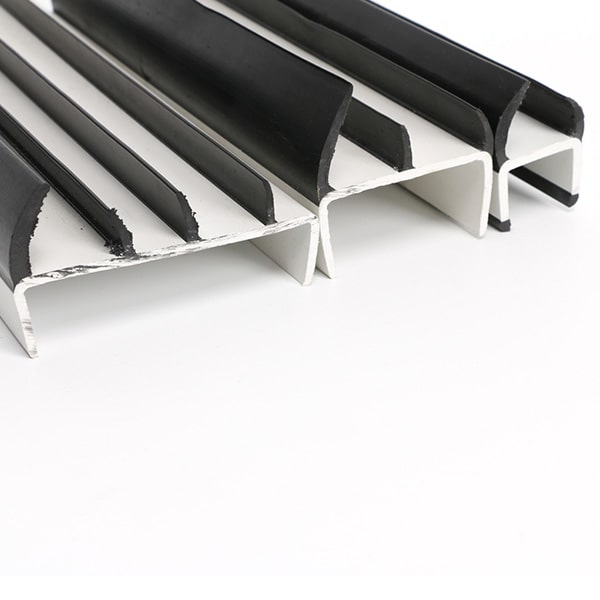

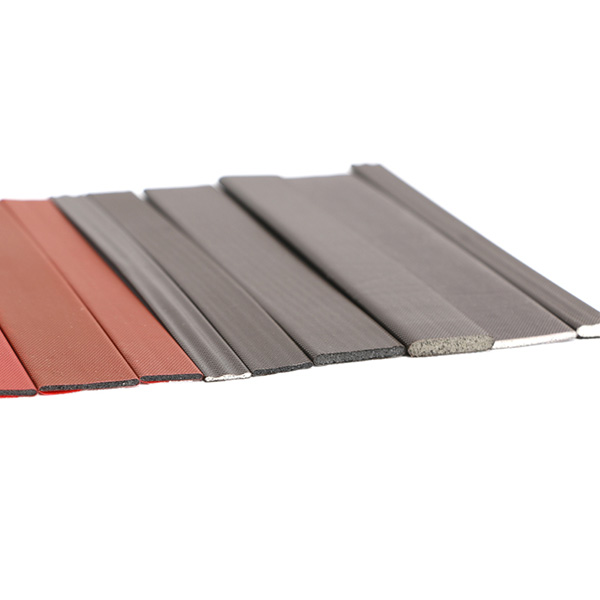

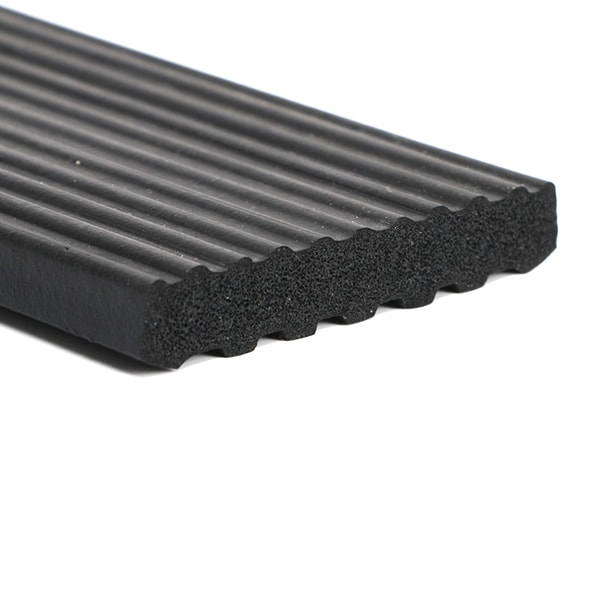

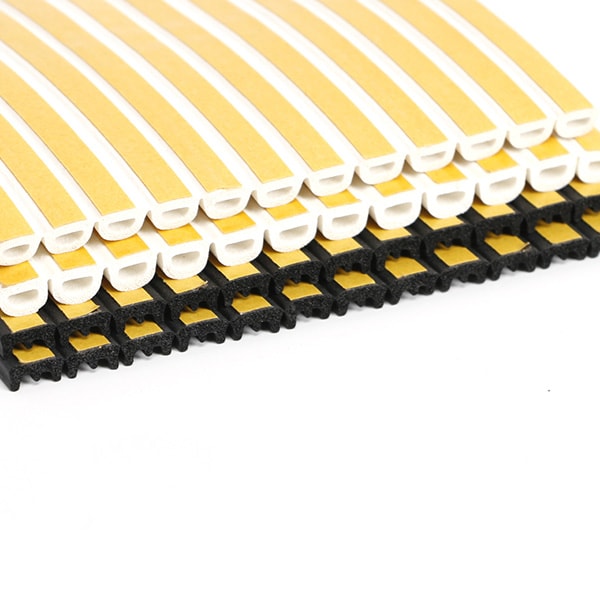

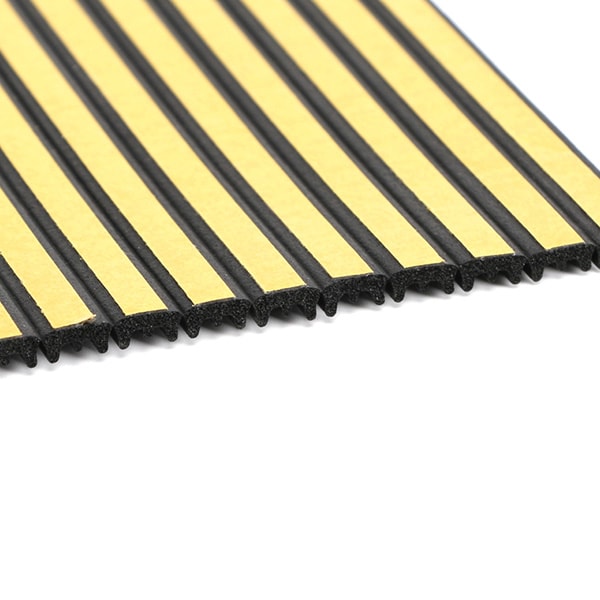

- EPDM Sponge Foam Sealing Rubber Strip

EPDM Sponge Foam Sealing Rubber Strip

- Brand: Jinjiu

- Product origin: China

- Delivery time: 5-7 days

- Supply capacity: 100000 meters/ day

Our Advantages

1. Specializing in production sealing strip.

2. An excellent team of highly qualified mangement and technicals personnel , and advanced production equipment.

3. 100% imported Dupont and LANXESS raw materials.

4. Production time: 5-7 days.

Features

1. Material: EPDM/Silicone/PVC/Neoprene.

2. Color: Various colors.

3. Size/Shape: Per customers' design, We have over 8000 styles available.

4. Hardness: 20 ~ 95 shore A.

5. Craft: Injection, extrusion and vulcanization.

6. Certificate: ISO9001:2000, ROHS, EPDM testing report.

7. Performance: Excellent chemical and physical stability, excellent in weather resistance, ozone resistance, anti-aging, electrical insulation,heat insulation, noise proof, high/low temperature-resistant, oil-resistant, dust-resistant.

8. Application: Al-alloy windows and door, curtain wall, machine system, Kitchen utensils, Appliances industries etc.

9. Production and shipment: MOQ:200kgs/style.

10. Production capacity: 10 tons/ Day.

11. Services: OEM services, free samples are available. Any questions and issues, Please feel free to contact us.

12. Packing: 10 kgs/roll, 2 rolls/weaven bag or according to customers requirement.

13. Deliver time: 7-10 days after order confirmed.

14. Payment: T/T, Western Union.

15. Feedback: Inquiries will be dealed within 48 hours.

Why more and more people choose EPDM seals

Ethylene propylene diene monomer (EPDM) rubber is synthetic rubber, the main component of which is ethylene (CH2 = CH - CH). Ethylene propylene trimer is synthesized by introducing the third monomer. Ethylene propylene rubber is basically a kind of saturated rubber. The main chain is composed of chemically stable saturated hydrocarbons. It only contains unsaturated double bonds in the side chain. There are no polar substituents in the molecule. The cohesion energy between molecules is low. The molecule chain maintains flexibility in a wide temperature range, so it has unique properties.

1. Low density and high filling property: EPDM is a kind of rubber with low density and its density is 0.87. Additionally, a large amount of oil and filler can be added, which can reduce the cost of rubber products, make up for the shortcomings of high raw rubber price of EPDM, and for EPDM with high Mooney value, the physical and mechanical properties of EPDM with high filling rate have little reduction.

23Aging resistance: Ethylene propylene rubber has excellent weather resistance, ozone resistance, heat resistance, acid and alkali resistance, water vapor resistance, color stability, electrical properties, oil filling and room temperature fluidity. Ethylene propylene diene monomer (EPDM) rubber products can be used for a long time at 120 C, ranging from 150 to 200. It can be used temporarily or intermittently under C. Adding suitable antioxidant can increase the use temperature. EPDM crosslinked with peroxide can be used under more stringent conditions. Ethylene propylene diene monomer (EPDM) rubber can be stretched 30% at ozone concentration of 50 * 10 ~, and can reach 150 h without cracking.

3. Corrosion resistance: Ethylene propylene rubber has good resistance to various polar chemicals such as alcohols, acids, alkalis, oxidants, refrigerants, detergents, animal and vegetable oils, ketones and fats due to its lack of polarity and low unsaturation, but it has poor stability in aliphatic and aromatic solvents such as gasoline, benzene and mineral oils. The performance will also decrease under the action of concentrated acid for a long time.

4.Water vapor resistance: Ethylene propylene rubber has excellent water vapor resistance and better heat resistance. In superheated steam at 230 C, there is no change in appearance after nearly 100 hours. Under the same conditions, the appearance of fluororubber, silicone rubber, fluorosilicone rubber, butyl rubber, nitrile rubber and natural rubber deteriorated significantly in a short time.

5. Superheater resistance: EPDM rubber also has better superheater resistance, but it is closely related to the vulcanization system used. Ethylene-propylene rubber (EPR) with dithiomorpholine and TMTD as vulcanization systems, after 15 months soaking in superheated water at 125 C, the mechanical properties changed little, and the volume expansion rate was only 0.3%.

EPDM has a good advantage over PVC, which is why more and more people choose EPDM sealing strips.

![1-min[2].jpg 1-min[2].jpg](https://img-MJvg40q38E6nIJAvRhSHiw.jumitop.cn/UpLoad/MJvg40q38E6nIJAvRhSHiw--/Images/202004/20200428214818300130.jpg)

Related Products

CONTACT US

HEBEI FARGO PLASTIC PRODUCTS CO., LTD.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us